Single Pipe Analysis

Step I: Liner Properties

Liner design service life (years):

The platform will calculate the minimum design liner thickness (TL) based on the service life (time in years) examined. Units are in years

Accepted Values: 0 to 100 years

(Click to see User Manual - Lined pipe analysis for more information)

Accepted Values: 0 to 100 years

(Click to see User Manual - Lined pipe analysis for more information)

Liner thickness (mm):

The service life of the lined pipe is estimated based on the liner thickness selected. Units are in mm. Liner thickness can be noted as just the reinforcing layer thickness (Tr) (for CIPP only) or total liner thickness (TL), however this must be noted by the applicator to avoid interchanging of terms.

Accepted Values: 0 ≤ TL ≤ 100 mm

Note: Thickness should be less than the internal radius of the pipe (D/2).

(Click to see User Manual - Lined pipe analysis for more information)

Accepted Values: 0 ≤ TL ≤ 100 mm

Note: Thickness should be less than the internal radius of the pipe (D/2).

(Click to see User Manual - Lined pipe analysis for more information)

Advanced Parameters (for the Liner) Click to show

Liner Properties:

.

Coefficient of thermal expansion (mm/mm/°C):

Coefficient of thermal expansion or contraction is the change in size with change in temperature. The units are in mm/mm/°C.

Accepted Values: 0 ≤ α ≤ 0.01

(Click to see User Manual - Lined pipe analysis for more information)

Accepted Values: 0 ≤ α ≤ 0.01

(Click to see User Manual - Lined pipe analysis for more information)

Short-term flexural modulus (hoop) (GPa):

Short-term (initial) flexural modulus of elasticity or Young’s modulus of the liner (Ef) (from wet testing – testing conducted with saturated specimens) is the stress divided by strain of the linear proportion of the stress strain curve. Testing is conducted in both axial and hoop directions (if liner is bidirectional, where subscript h is in the hoop direction and subscript a is in the axial direction). Testing is conducted from flexural tests (ISO 14125 1998, AS 1145 2001, ASTM D790 2017) and units are in GPa.

Accepted Values: 0.01 ≤ Efh ≤ 100 GPa

(Click to see User Manual - Lined pipe analysis for more information)

Accepted Values: 0.01 ≤ Efh ≤ 100 GPa

(Click to see User Manual - Lined pipe analysis for more information)

Short-term flexural modulus (axial) (GPa):

Short-term (initial) flexural modulus of elasticity or Young’s modulus of the liner (Ef) (from wet testing – testing conducted with saturated specimens) is the stress divided by strain of the linear proportion of the stress strain curve. Testing is conducted in both axial and hoop directions (if liner is bidirectional, where subscript h is in the hoop direction and subscript a is in the axial direction). Testing is conducted from flexural tests (ISO 14125 1998, AS 1145 2001, ASTM D790 2017) and units are in GPa.

Accepted Values: 0.01 ≤ Efa ≤ 100 GPa

(Click to see User Manual - Lined pipe analysis for more information)

Accepted Values: 0.01 ≤ Efa ≤ 100 GPa

(Click to see User Manual - Lined pipe analysis for more information)

Adhesion strength of the liner to host pipe substrate (MPa):

Adhesion strength of the liner to host pipe substrate. Adhesion tested on a variety of surfaces, including CML (if CML lined pipe) shall be determined using any or all of the following standards: ASTM D4541 for metal, ASTM D7234 for AC and CML, or Pull off adhesion testing to AS 3894.9 for all CIPP classes that require adhesion for sealing (e.g. at ends or service connections) or bonding to the host pipe (Class C). Units are in MPa.

Accepted Values: 0 ≤ σad ≤ 100 MPa

(Click to see User Manual - Lined pipe analysis for more information)

Accepted Values: 0 ≤ σad ≤ 100 MPa

(Click to see User Manual - Lined pipe analysis for more information)

Factor of safety for liner imperfections:

Factor of safety for liner imperfections (variable wall thickness in polymeric spray lining and folds in CIPP lining), depends on the imperfection type. The following factors of safety for liner imperfections can be used:

Uneven thickness (polymeric spray), Ni=1.5

Folds (CIPP), Ni=2

Accepted Values: 1 ≤ Ni ≤ 5

(Click to see User Manual - Lined pipe analysis for more information)

Uneven thickness (polymeric spray), Ni=1.5

Folds (CIPP), Ni=2

Accepted Values: 1 ≤ Ni ≤ 5

(Click to see User Manual - Lined pipe analysis for more information)

Wet reduction factor:

If the liner is subjected to plasticisation due to water saturation a wet strength reduction factor must be applied to reduce short-term and long-term strength properties. Ideally, testing should be conducted in wet conditions if liner plasticises when saturated. This is more common in polymeric spray liners than CIPP liners. The wet factor reduction ranges from 0.5-1, however the default value is set as 1 in the Monash Pipe Evaluation Platform as the tests are assumed to be conducted in water.

Accepted Values: 0.5 ≤ φs ≤ 1

(Click to see User Manual - Lined pipe analysis for more information)

Accepted Values: 0.5 ≤ φs ≤ 1

(Click to see User Manual - Lined pipe analysis for more information)

Cyclic surge or pressure transient properties:

.

Pressure transient factor:

A pressure transient factor (nf) of 2 (conservative case) or the following equation is used to account for the second cycle onwards in a pressure transient.

nf=1+1/((∆σ0)/(∆σ1))^3.2

Where nf is the cyclic surge factor, ∆σ0 is the primary pressure transient wave stress change and ∆σ1 is the secondary pressure transient wave stress change.

Accepted Values: 1 to 2

(Click to see User Manual - Lined pipe analysis for more information)

nf=1+1/((∆σ0)/(∆σ1))^3.2

Where nf is the cyclic surge factor, ∆σ0 is the primary pressure transient wave stress change and ∆σ1 is the secondary pressure transient wave stress change.

Accepted Values: 1 to 2

(Click to see User Manual - Lined pipe analysis for more information)

Total number of surge pressure cycles for service life of pipe/lined pipe:

The total number of surge cycles or pressure transients expected for the service life of the pipe/lined pipe. The number is calculated from the number of recurring pressure transients per day multiplied by the number of days in the service life of the pipe multiplied by a cyclic surge factor.

nTPC=nf × nPC × no. of days

Accepted Values: 0 ≤ nTPC ≤ 107

(Click to see User Manual - Lined pipe analysis for more information)

nTPC=nf × nPC × no. of days

Accepted Values: 0 ≤ nTPC ≤ 107

(Click to see User Manual - Lined pipe analysis for more information)

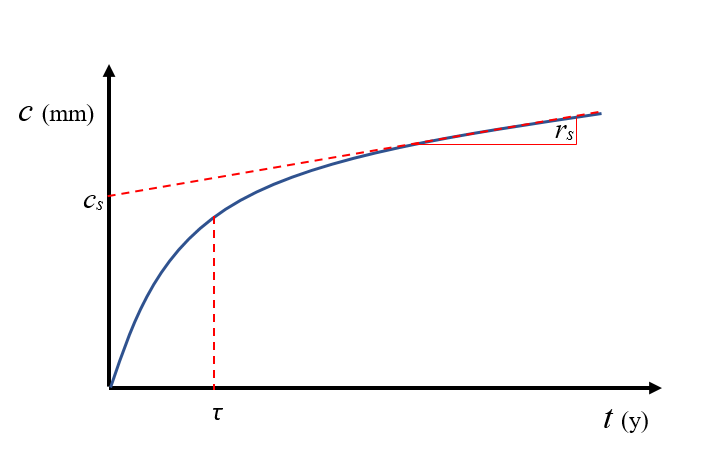

Reduction curves of liner long-term properties as a function of time due to deterioration: