Pipe Level Analysis

Pipe level analysis is conducted on individual lengths of pipe. Leak records and break records are used to determine what method of renovation or replacement is best suited to the high ranked pipes. An estimation from records is used to determine a defect size for long-term calculations.

Workflow to analyse liner requirements based on individual pipe segments

Step I: Failure History

Step II: Deterioration

Pipe segment installation year:

Construction year of the pipe, burial year of the pipe or pipe installation year.

Accepted Values: 1850 to 2021

(Click to see User Manual - Pipe failure analysis for more information)

Accepted Values: 1850 to 2021

(Click to see User Manual - Pipe failure analysis for more information)

Pipe material:

Pipe material type including metallic and cement pipes.

Accepted Values: CI, CICL, AC

(Click to see User Manual - Liner selection for more information)

Accepted Values: CI, CICL, AC

(Click to see User Manual - Liner selection for more information)

Pipe nominal diameter (mm):

Internal diameter of the pipe. Typically, the nominal diameter is expressed in mm conveniently rounded to roughly the manufactured internal diameter, however the imperial terms use inches.

Accepted Values: 50 to 1500 mm

(Click to see User Manual - Pipe failure analysis for more information)

Accepted Values: 50 to 1500 mm

(Click to see User Manual - Pipe failure analysis for more information)

Pressure head:

The operating pressure converted to a meter head value, particularly used in leak rate calculations. Units are in m.

Accepted Values: 0 to 300 m

(Click to see User Manual - Liner selection for more information)

Accepted Values: 0 to 300 m

(Click to see User Manual - Liner selection for more information)

Soil Type:

The soil type names are from AS 4419 (2018). The users can select a soil type from the list and the soil properties will be prefilled. Soil type could be any of the following soils:

Accepted Values: sand, loamy sand, sandy loam, fine sandy loam, loam, silty loam, sandy clay loam, fine sandy clay loam, clay loam, silty clay loam, sandy clay, light clay, silty clay, medium clay, heavy clay

(Click to see User Manual - Pipe failure analysis for more information)

Accepted Values: sand, loamy sand, sandy loam, fine sandy loam, loam, silty loam, sandy clay loam, fine sandy clay loam, clay loam, silty clay loam, sandy clay, light clay, silty clay, medium clay, heavy clay

(Click to see User Manual - Pipe failure analysis for more information)

Corrosivity level:

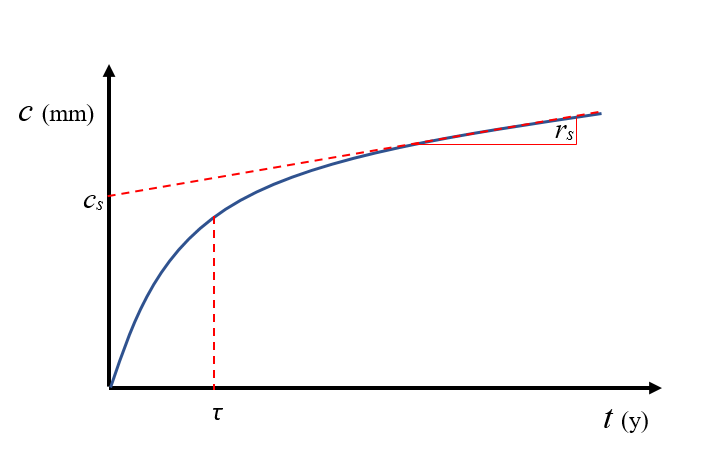

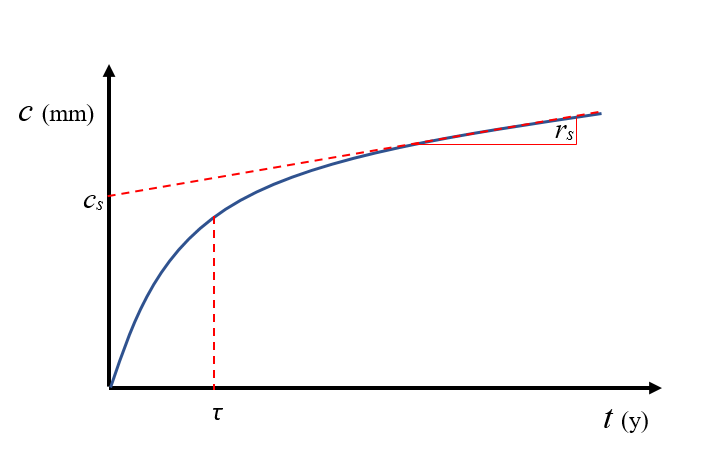

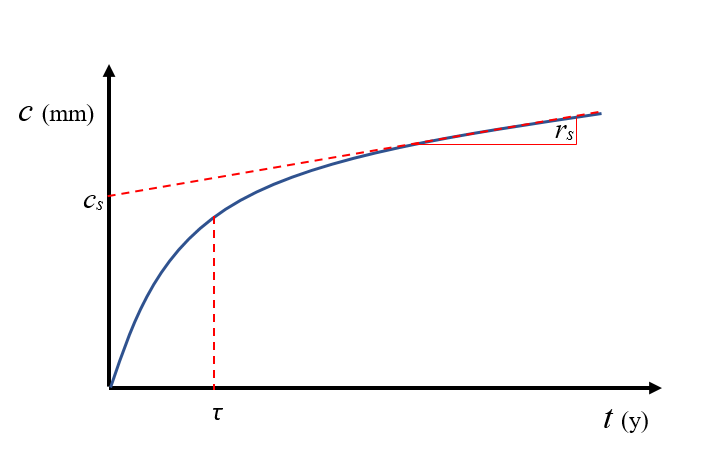

Used for metallic pipes to determine the:

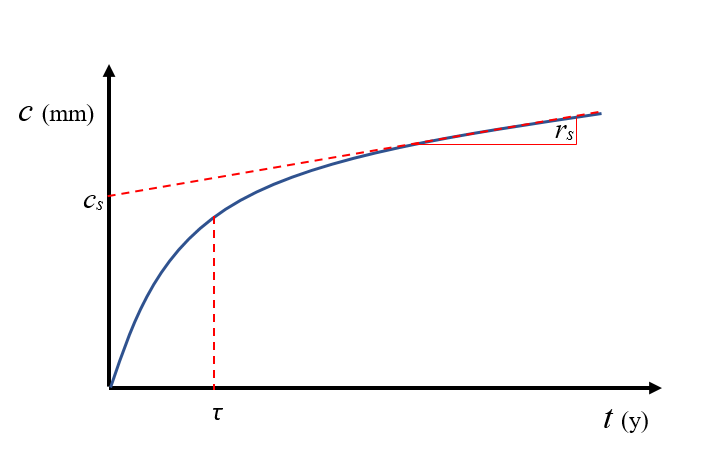

Long-term, steady state corrosion rate, rs

Intercept parameter for long-term corrosion, cs

Transition period between short-term and long-term corrosion, τ

Accepted Values: Very low, low, moderate, high, very high

(Click to see Theory Manual - Liner selection for more information)

Long-term, steady state corrosion rate, rs

Intercept parameter for long-term corrosion, cs

Transition period between short-term and long-term corrosion, τ

Accepted Values: Very low, low, moderate, high, very high

(Click to see Theory Manual - Liner selection for more information)

Advanced Parameters Click to show

Long-term, steady state corrosion rate of metallic pipes:

Click to see the image Power law model used for corrosion level estimation for more information.

Accepted Values: 0 ≤ rs ≤ 1

(Click to see Theory Manual - Liner selection for more information)

Accepted Values: 0 ≤ rs ≤ 1

(Click to see Theory Manual - Liner selection for more information)

Intercept parameter for long-term corrosion of metallic pipes:

Click to see the image Power law model used for corrosion level estimation for more information.

Accepted Values: 0 ≤ cs ≤ 50

(Click to see Theory Manual - Liner selection for more information)

Accepted Values: 0 ≤ cs ≤ 50

(Click to see Theory Manual - Liner selection for more information)

Internal deterioration rate for AC pipes:

Internal deterioration rate for AC pipes. Rates can be calculated from phenolphthalein testing or approximated based on utility data. Units are in mm/y.

Accepted Values: 0 ≤ cACi ≤ 1 mm/y

(Click to see Theory Manual - Liner selection for more information)

Accepted Values: 0 ≤ cACi ≤ 1 mm/y

(Click to see Theory Manual - Liner selection for more information)

External deterioration rate for AC pipes:

External deterioration rate for AC pipes. Rates can be calculated from phenolphthalein testing or approximated based on utility data. Units are in mm/y.

Accepted Values: 0 ≤ cACi ≤ 1 mm/y

(Click to see Theory Manual - Liner selection for more information)

Accepted Values: 0 ≤ cACi ≤ 1 mm/y

(Click to see Theory Manual - Liner selection for more information)

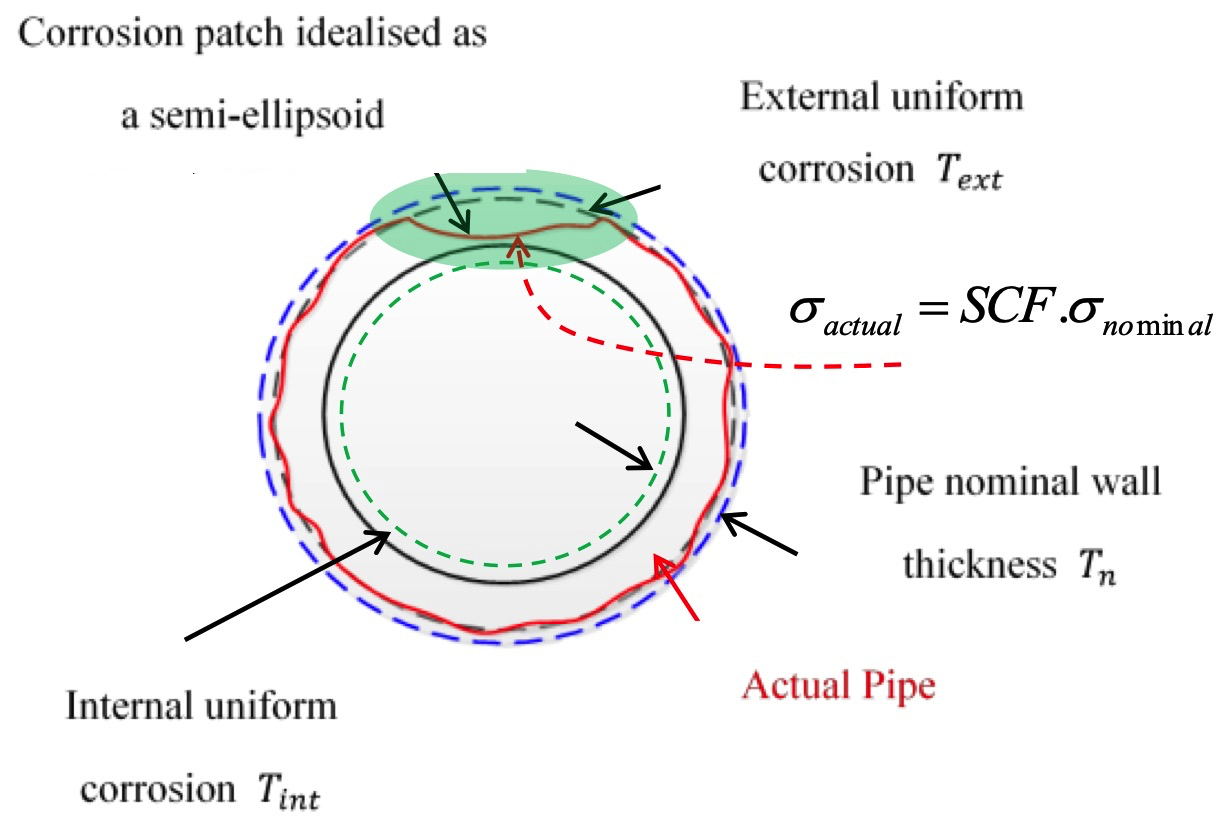

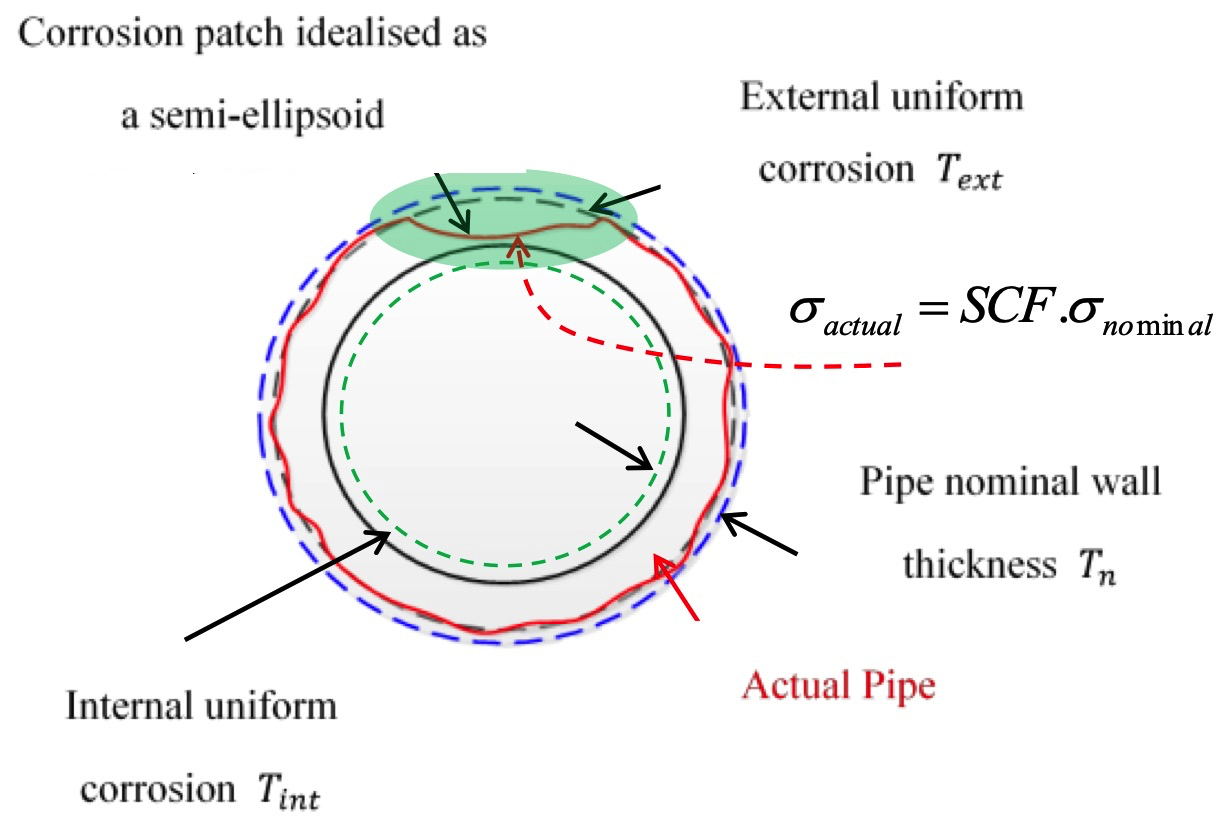

Pipe nominal wall thickness (mm):

Original wall thickness. Click to see the image Cross section of a corroded pipe for more information.

Accepted Values: 0 < Tn ≤ 50 mm

(Click to see User Manual - Pipe failure analysis for more information)

Accepted Values: 0 < Tn ≤ 50 mm

(Click to see User Manual - Pipe failure analysis for more information)

Step III: Leak Rates

Leak rate:

Leak rate of a pipe is the measure of water escaping a pipe due to a defect. It can be measured in L/s. Leak rate is used only if water utilities have this value to determine a defect size based on the Orifice equation.

Accepted Values: 0 ≤ Q ≤ 500 L/s

(Click to see User Manual - Liner selection for more information)

Accepted Values: 0 ≤ Q ≤ 500 L/s

(Click to see User Manual - Liner selection for more information)

Pressure head:

The operating pressure converted to a meter head value, particularly used in leak rate calculations. Units are in m.

Accepted Values: 0 to 300 m

(Click to see User Manual - Liner selection for more information)

Accepted Values: 0 to 300 m

(Click to see User Manual - Liner selection for more information)

Advanced Parameters Click to show

Discharge coeffiecient:

The Discharge coefficient is a non-dimensional constant used in the Orifice equation and is estimated to be 0.61. Typically between 0.6 to 0.85.

Accepted Values: 0 to 1

(Click to see User Manual - Liner selection for more information)

Accepted Values: 0 to 1

(Click to see User Manual - Liner selection for more information)

Liner Recommendation

CONDITION GRADE:

Failure History

-

Deterioration

-

Leak Rates

-

Recommendation Options:

Detailed Results : Maximum Defect SizeClick to show

Assuming Elliptical Defect

Assuming Circular Defect

Assuming Gap Defect